Capabilities

At Continental, we fuse imagination, functionality, and aesthetics to create exceptional architecture.

That’s why architects, general contractors, and their clients rely on us for the highest quality millwork and casework in the greater New England and New York areas.

Our intimate knowledge of materials and finishes, combined with decades of experience in design and project management, are why we’ve been a trusted partner for projects ranging from $50k to well over $1 million in value.

Whether contemporary or classic design, familiar or rare woods, solid surfaces or laminates, metals or solid resins—whatever your vision, whatever millwork challenges you face, you can depend on Continental Woodcraft.

We take great pride in what we do. Our quality of craftsmanship is all the proof you’ll need.

We Bring Complex Designs to Life

We’re well-versed in the bidding processes for retail, healthcare, education, government, and municipality. We carry this efficiency through our project management process from initial drawings to detailed blueprints and fabricated, finished pieces. Our project managers are your direct points of contact and work closely with you and our engineering and manufacturing staff to ensure that our project flow meets your project schedule.

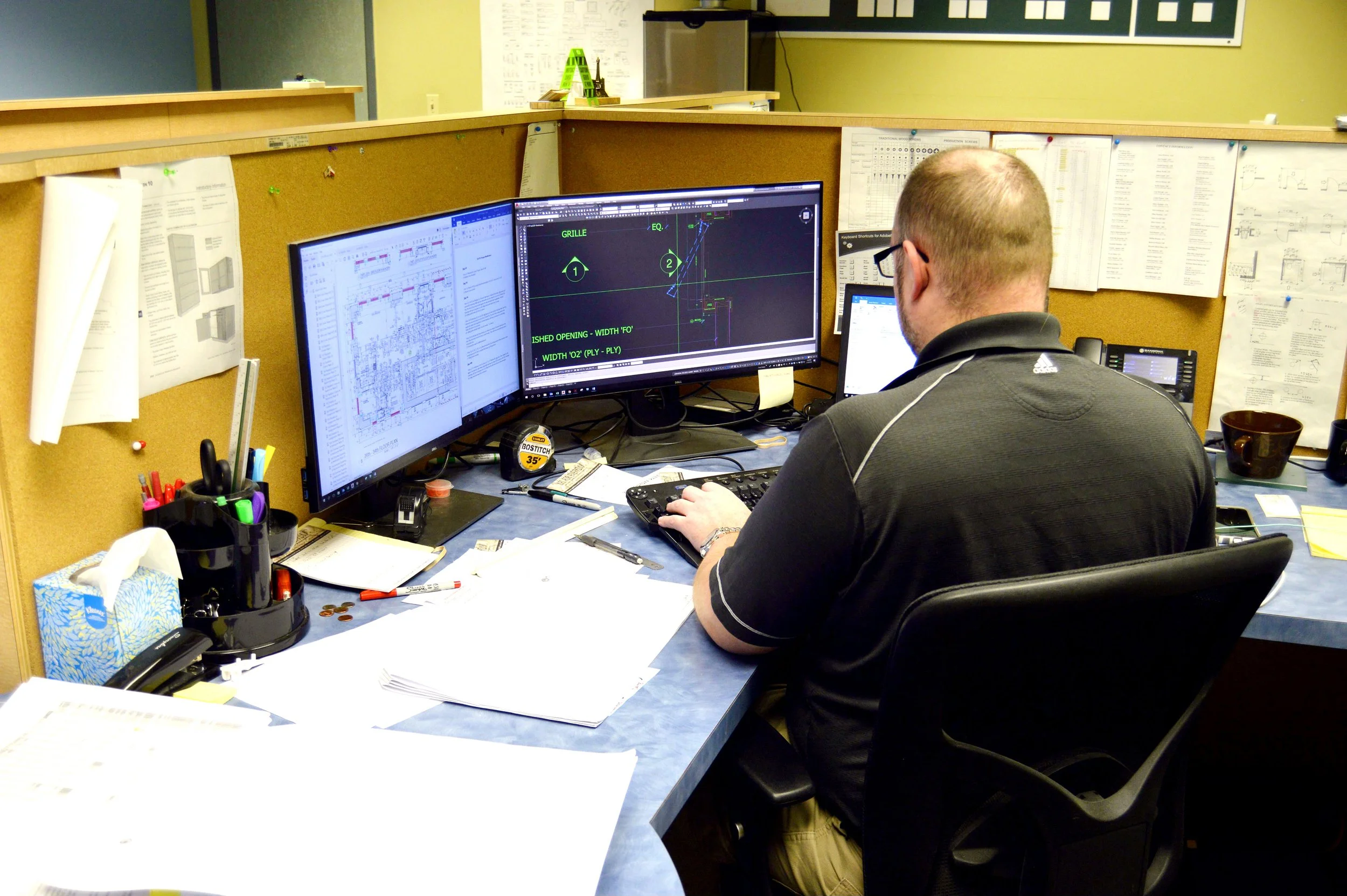

Engineering

Our talented engineering staff uses the latest technology and 3D engineering software to handle projects of any size and with even the most stringent of requirements. With expert precision, they produce all the required technical submittals, finish samples, shop drawings, and field dimensions necessary to move the project into production.

Before manufacturing begins, we coordinate with your field personnel and other trades so that the design’s intention is strictly adhered to, proactively providing an efficient and quality product at every stage.

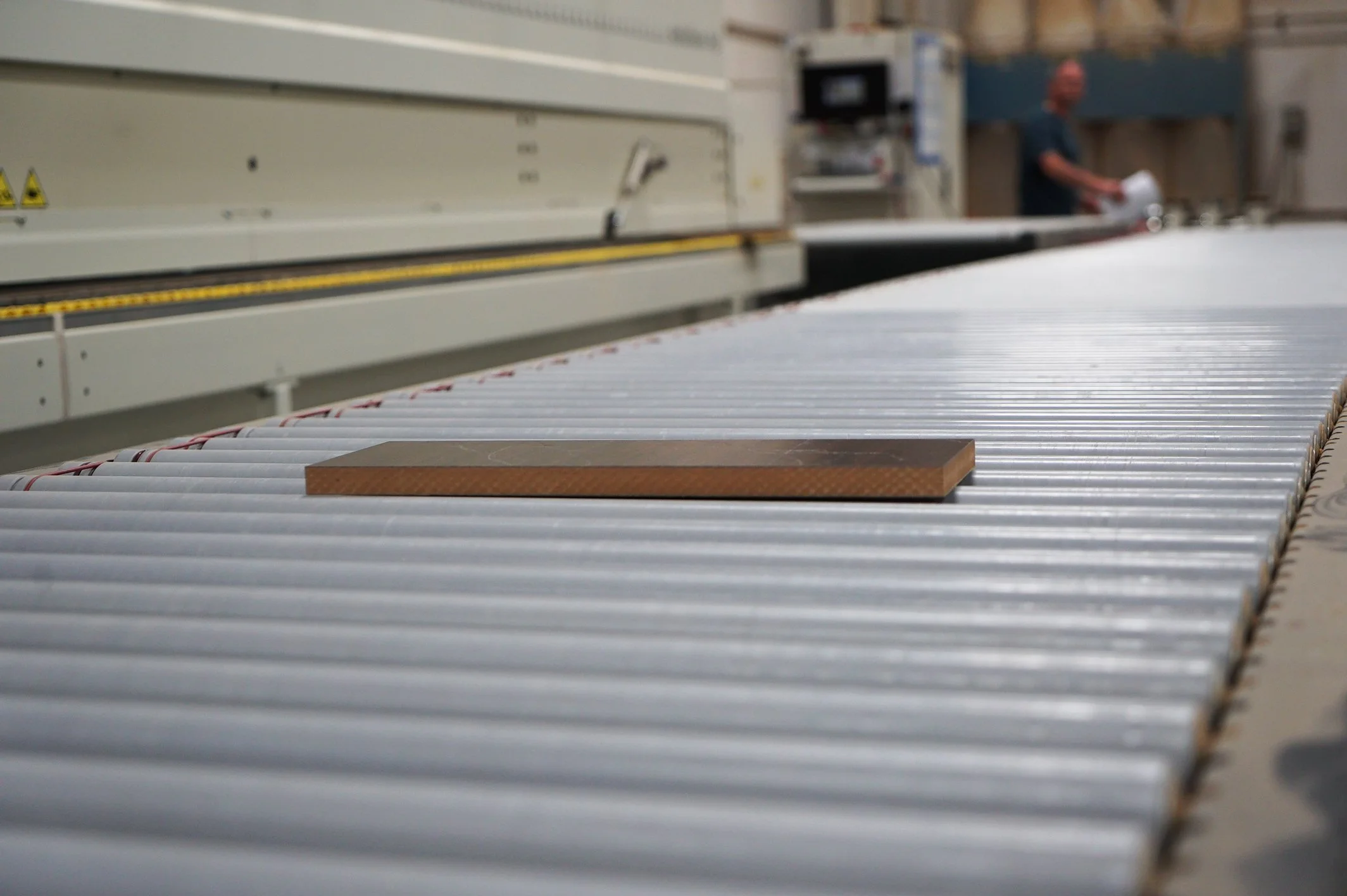

Manufacturing & Finishing

With state-of-the-art machinery and a staff of certified Journeymen, highly skilled cabinet makers, machine operators, and finishers, we provide quality products at an optimum value. Even the most complex shapes can be machined efficiently and accurately. Color matching, solid surface, and pre-finishing needs are a cinch.

The proficiency of our finishing departments allows us to process projects efficiently and quickly without a loss in consistency and precision. Combined with our in-house graphic production capabilities and installation services, we can meet all your millwork needs.

Special Projects

As a mark of sophistication, we are certified by SCS Global Services to the prestigious FSC® certification standards and can work on special, FSC-certified millwork projects. The Forest Stewardship Council®, or FSC, is the most rigorous international standard for responsible forestry. If you require an FSC-certified organization for your project, we’re ready and able to serve you.